Want to sell microgreens to grocery stores without wasting time on guesswork. This guide shows exactly how to land accounts, set repeat orders, and keep products moving off the shelf.

You will learn the research steps to confirm demand, how to approach the produce manager, what sample sizes to bring, and how to match packaging to sliders, shelves, or wells. We cover pricing tiers, UPC-ready labels, shopper-friendly dating, and weekly delivery rhythms that retailers love.

Expect practical numbers too, like scaling from about 30 to 40 trays per week to roughly 200, and sales jumps after organic certification.

With scripts, a fresh sheet, and tight operations for airflow, watering, and seed lots, you can build reliable store partnerships.

Why sell microgreens to grocery stores

Grocery stores buy on a schedule, value reliable quality, and reward clear presentation. That mix makes them a steady channel compared with weekend markets, where weather, setup, and a short sales window can limit revenue. When a store program is tuned well,l it can scale fast. A grower serving New York City moved from roughly thirty to forty trays per week to about two hundred trays per week in under a year once stores adopted the line. After earning organic certification, access to top independents expanded, ed and weekly sales roughly doubled within about six weeks. Stores respond when deliveries are on time, labels are easy to read, packs look full in the case, and the producer is simple to work with.

Presentation matters as much as product. Wide and flat clamshells show the greens clearly and help them sell. Waterproof labels that can be read from a few feet away help shoppers decide quickly. Add predictable weekly delivery and basic shelf service, and you become a low-friction supplier the produce manager can trust.

Do smart recon before you pitch.

Walk the exact stores you want to supply. If microgreens are already on the shelf, treat that as proof of demand. Record retail prices, label quality, pack formats, and freshness. Study where the product sits because placement changes everything. Some stores use narrow slider rails. Others rely on standard shelves. Many have deep wells near the bottom of a case. Each location favors a different pack shape and affects how full the product looks after a few days.

If you do not see microgreens, ask the reason. Sometimes, shoppers in that area have never been introduced to the category. Sometimes a previous supplier delivered inconsistently or used packs that settled and looked half empty. Sometimes the store has been looking for a local option and could not find one. While you are there, decide where your items would physically fit. Slim and wide packs suit the sliders. Deeper packs stand well on shelves. Wells are challenging because they sit out of eye level, and greens can settle, so plan accordingly.

🌿 Recommended Microgreens Supplies |

Find the decision maker and book the right meeting.

Decisions usually sit with the produce manager or with a buyer who may purchase for several locations. In some cases that buyer covers five to ten stores. Call the store, learn the name of the produce manager, and ask for a short morning appointment. Mornings work because many produce managers handle ordering and merchandising early in the day. Do not drop in while they are stocking. A planned visit earns attention and shows respect for their time.

Your aim in that first meeting is simple. Place sealed, retail-ready samples in their hands, show exactly where those items would live in the case, and leave a clear one-page fresh sheet. Keep it brief and useful.

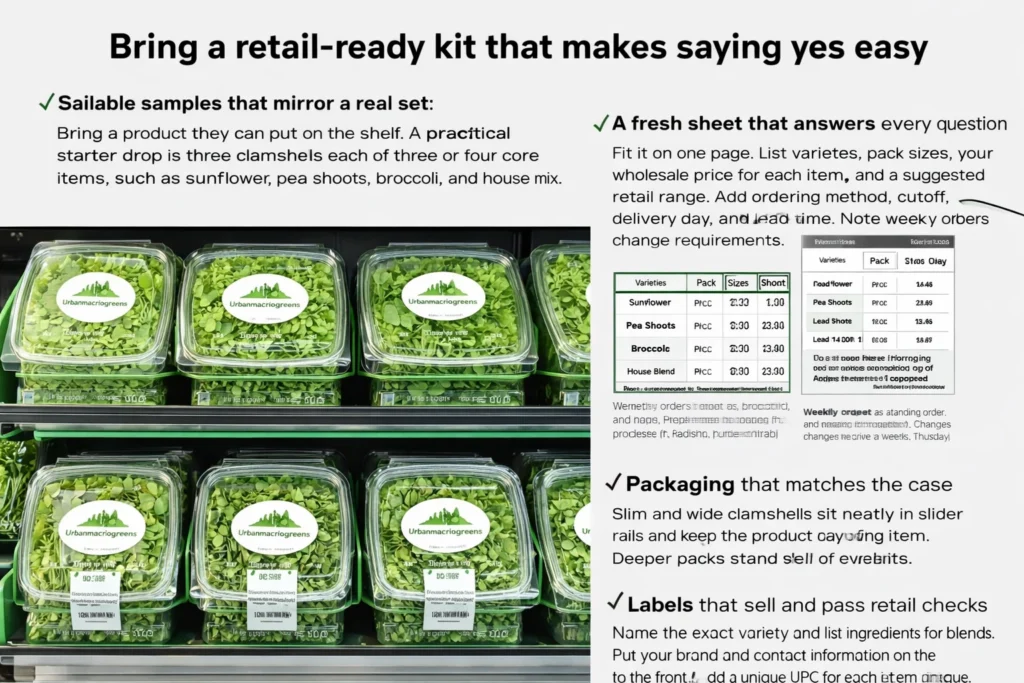

Bring a retail-ready kit that makes saying yes easy.

Sailable samples that mirror a real set

Bring a product they can put on the shelf. A practical starter drop is three clamshells each of three or four core items, such as sunflower, pea shoots, broccoli, and a house mix. Growers who use this approach routinely invest about fifty to sixty dollars in that first placement. It functions as real-world market research for both sides.

A fresh sheet that answers every question

Fit it on one page. List varieties, pack sizes, your wholesale price for each item, and a suggested retail range. Add ordering method, order cutoff, and your delivery day. State lead time clearly. Ten to fourteen days is typical for new items or changes because you grow to order. Note that weekly orders repeat as a standing order and that any change requires two weeks’ notice so you can adjust sowing.

Packaging that matches the case

Slim and wide clamshells sit neatly in slider rails and keepthe product looking full. Deeper packs stand well on shelves. Deep wells near the bottom are the toughest position because visibility is low, and greens can settle. If a store relies on wells, consider a taller pack and a wrap label that is easy to read from above.

Labels that sell and pass retail checks

Name the exact variety and list ingredients for blends. Do not call a blendof arugula if it contains mostly pea. Put your brand and contact information on the front. Add a unique UPC for each item rather than relying on generic store codes. Use a shopper-friendly date system. Many growers place a small Julian pack code on the back so the store can rotate stock without confusing shoppers with harvest or expiry stamps. Local health rules vary. Some regions expect a date on the label. Some farm-related labeling scenarios in the United States include a full farm address once average annual sales exceed about five hundred fifty thousand dollars across a three year period. Confirm local rules with your health or agriculture department.

Run the meeting like a category partner.

Show exactly where your items fit and why. If eye-level facings are possible, point to the spot and explain the pack that belongs there. Share which packs suit sliders versus shelves. Ask which varieties move best with their customers and whether there have been shelf life concerns with previous suppliers. Leave your sailable samples and fresh sheet, collect phone and email, and set a friendly follow-up for the next week or two. The aim is to learn what will help their set turn reliably and to show that you will be easy to work with.

Use pricing and pack architecture that match how people buy

Shoppers decide fast and often from a few feet away. Offer a small range of price points by varying the net weight per item. A workable pattern is half an ounce for basil or cilantro, one ounce for watercress or broccoli, and two and a half ounces for sunflower or pea packed in a twenty-four fluid ounce clamshell. That structure lets the store keep everyday items under five dollars, a threshold many customers notice, while offering a premium house mix around seven to eight dollars for those who want a special blend. One New York seller used exactly this approach, with sunflower and pea positioned below five dollars after margin and a five-variety salad style mix in the seven to eight dollar range.

Group items into simple tiers so ordering stays clear. Keep label design consistent across tiers so the set looks like a family on the shelf.

Set orders, pars, and a delivery rhythm the store can rely on

Start with one or two stores and a modest weekly standing order. Stock and face the product when you deliver, so the case looks right immediately. Follow up after about one to two weeks to review what sold and what sat. A weekly call on Monday works well. Ask what is left today, whether anything sold out early, and whether the coming week looks busy. Use those details to set the next paragraph. Many small suppliers keep shrinking extremely low by undersupplying at first and growing pars slowly once they see steady sales through. Mature accounts often run near zero buyback because the par is tuned to demand.

Put the rules in writing. Standing orders repeat each week unless changed. Changes require twoweeks’s notice because you grow to order and typical lead times for new items or adjustments sit in the ten to fourteen day range. Deliver on the same day and within the same window each week, so staff can plan. When you run this rhythm consistently,y you become part of the store routine, which is exactly where you want to be for long term microgreens sales.

Set a clear stance on buybacks.

Some stores expect you to take responsibility for slow movers. Others prefer to manage themselves. Decide your approach before the first order and communicate it in simple terms. Independent stores often appreciate a small safety net, while larger chains usually operate without credits.

A common starting point is to make replacements an occasional goodwill gesture rather than a standing promise. One or two units swapped at the next delivery shows partnership without turning credits into a habit. Another workable model is a tiny credit on a rare stale unit while pricing wholesale a touch higher to fund that risk. Producers who tune pars tightly often reportnear-zeroo to five percent buyback once the account is stable. Many sellers avoid the issue entirely with larger chains by running no buybacks and focusing on accurate parts and consistent rotation.

Whichever model you choose, keep initial pars conservative and grow them only after you see steady-weekly availability without sellouts. That single habit protects both sides and keeps shrinking.

Protect shelf life with tight operations.

Airflow and temperature that stay steady

Moving air prevents moisture from lingering and helps greens dry after irrigation. Use a mix of oscillating and directional fans so air rolls through the room rather than blasting plants. An exhaust on a thermostat brings in fresh air and keeps the room fromgetting toog warm, which matters for herbs like cilantro that dislike heat. In a compact grow space, vertical circulation helps even out temperatures from top to bottom and reduces wet corners that invite problems.

Germination setup that breathes

Fill the soil level with the tray lip so stacked trays still have a gap for air. When soil sits low in the tray and the upper tray overlaps deeply, you create a stale pocket that can foster white fuzz on crops like sunflowers. Uncover into strong airflow and let canopies dry fully before harvest. Radis,h in particular, ar tends to stay wet unless it gets directed air.

Watering that respects the crop. Sunflowers

Sunflowers can tolerate a brief wilt and bounce back quickly after water. Pea shoots do not. If peas dehydrate to the point of limp tissue, they rarely regain that plump bite. Keep pea trays evenly moist and avoid swings. In warm months, you may move from once daily to a morning and evening pattern to stay consistent.

Seed lots that are actually consistent

Sunflower seed varies more than most. Different lots can change germination, stem size, disease susceptibility, and time to true leaves. Test small when a new lot arrives. When you find a winner, buy enough to carry you because a good lot may disappear quickly. Many growers favor larger seed from North American sources for reliable performance, even if debris cleaning takes a bit more care. Routine sanitation matters too. Some operators add a light seed rinse or amid-germination sanitizer mist in tough stretches, and they keep a regular wash schedule for trays and benches with a yearly deep clean.

Package tests that reflect store reality

Stage finished packs in a cooler for a full week, the way they will sit in the case. Watch for settling that makes a deep clamshell look half empty by day two, and for condensation that clouds lids. Adjust pack shape and label placement until the product still reads full and fresh at week’s end.

Certifications and compliance that open doors

Organic certification can be a fast way to reachtop-tierr independents. One seller who earned certification saw weekly sales roughly double in about six weeks because more stores began to carry the line. If organic is part of your plan, build your record-keeping early so the audit is easier, and your labels are complete.

Label basics include clear variety names, ingredients for blends, your brand and contact information, and a unique UPC for every SKU. A date system helps staff rotate stock while avoiding shopper confusion. Many producers place a small Julian pack code on the back rather than large harvest or expiry stamps that can scare customers,s even when the product is still in great shape. Local health departments may expect a date on the label and can advise on format. Somfarm-related labeling scenarios in the United States also include a full farm address once average annual sales are around five hundred fifty thousand dollars across a three year period. Always confirm rules with your local health or agriculture office so your paperwork matches your region.

Plan for seasonality and adjust your store mix.

City stores can go quiet in the summer when residents travel,l and outdoor markets pull attention. One seller in the Northeast noted that urban stores felt empty in the warm months, while microgreens moved strongly the rest of the year. If you see the same pattern, transplant for summer, keep the set tight to proven movers such as broccoli, pea shoots, sunflower, and a house mix, and rely more on other channels for a few weeks. When the city fills back up, restore normal pars and facings.

Placement matters even more during slow periods. Eye-level positions and slider rails help packs read full at a glance. Deep wells at the bottom of the case are the hardest location because visibility is poor, and greens can settle. If wells are unavoidable, use taller packs and wrap labels that are easy to read from above,e and plan for smaller quantities.

Two week launch plan you can actually run

Week one

Walk three to five target stores and document prices, placements, and pack styles that fit each case. Finalize four SKUs that cover everyday staples and one premium blend. Print waterproof labels with clear branding and a UPC for each item. Build a one-page fresh sheet that lists varieties, pack sizes, wholesale and suggested retail, order method, and cutoff, delivery day, and lead time. Call to learn the produce manager’s name and book short morning appointments. Drop sailable samples that mirror a real mini set. Expect to invest about fifty to sixty dollars’ worth of product for each trial.

Week two

Follow up by phone within a week to ten days. Ask what sold, what sat, and whether the coming week looks busy. Set a small standing order and place your first delivery on a predictable day and time. Stock and face the set yourself so it looks right the moment you leave. Tune pars conservatively so the case still has product late in the week without causing returns. In parallel, test any new sunflower seed lots on a small scale and line up a larger purchase if performance is strong,g so your yields do not wobble mid-season.

Reusable tools that save time every week

Short scripts that lower the barrier

A simple opener can be all you need.

Hi, I am with [Farm]. I would love to bring sealed, shelf-ready microgreens and a one-page info sheet. Can we do a ten-minute walk-through one morning this week?

A clean follow-up keeps momentum.

Quick check on the microgreens. What is left today? Did anything sell out early? Let us set next week at [counts by SKU]. I will rotate and face the set on delivery.

A one-page fresh sheet that answers every question

Include varieties and pack sizes, wholesale and suggested retail, order method and cutoff, delivery window, lead time of ten to fourteen days for new items or changes, standing order with two weeks’ notice for adjustments, and full contact information. Keep the design readable so it can live in the production office.

A case checklist you can carry in your pocket

Measure slider rails and shelf depths. Note the positions that are true eye level. Record competitor prices and which shapes look full after a few days. Confirm whether the department prefers wrap labels or top labels for visibility. Capture the produce manager’s preferred contact method and the best time to call each week.

These small tools help you show up prepared, make clear promises, and keep your products in the best spot in the case. Over a few cycles, they turn a trial placement into a steady weekly program that pays you back with reliable sales.